Expert in Passive Fire Protection Solutions

- Fire rated Partition & Ceiling systems

- Fire-rated Ductwork – Ventilation & Smoke Extract Duct Protection

- Fire-rated M&E Service Enclosures

- High-Performance Fire Barrier

- Industrial Fire & Blast Barrier system

- Calcium silicate partition for Wet areas & External partition

- Fibre cement boards

- External Cladding panels

Passive Fire Protection (PFP) is the first line of defense in the preventing the spread of fire. As opposed to active fire suppression, such as fire extinguishers and sprinkler systems, passive fire protection doesn’t actively put the fire out. Its aim is to contain the fire and smoke within a compartment of the building, allowing the safe evacuation of the property, and preventing further damage to the structure. If the location of the fire prevents the evacuation of all areas, then passive fire systems provide protection to any trapped personnel allowing the fire brigade to attend the scene, and effect the safe removal of those trapped. An important piece of fire protection advice to remember is that passive fire protection can, and does, save lives as well as property.

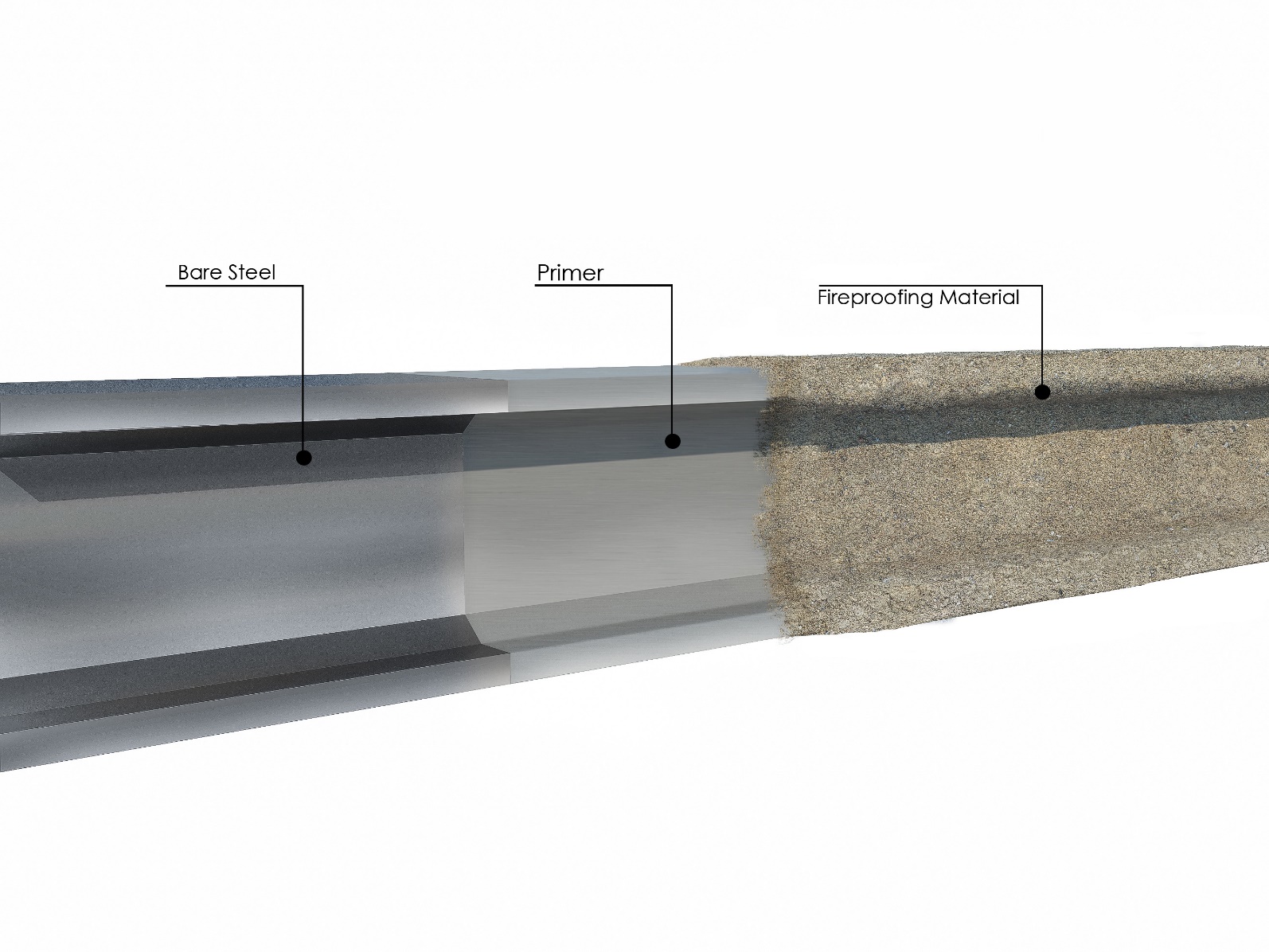

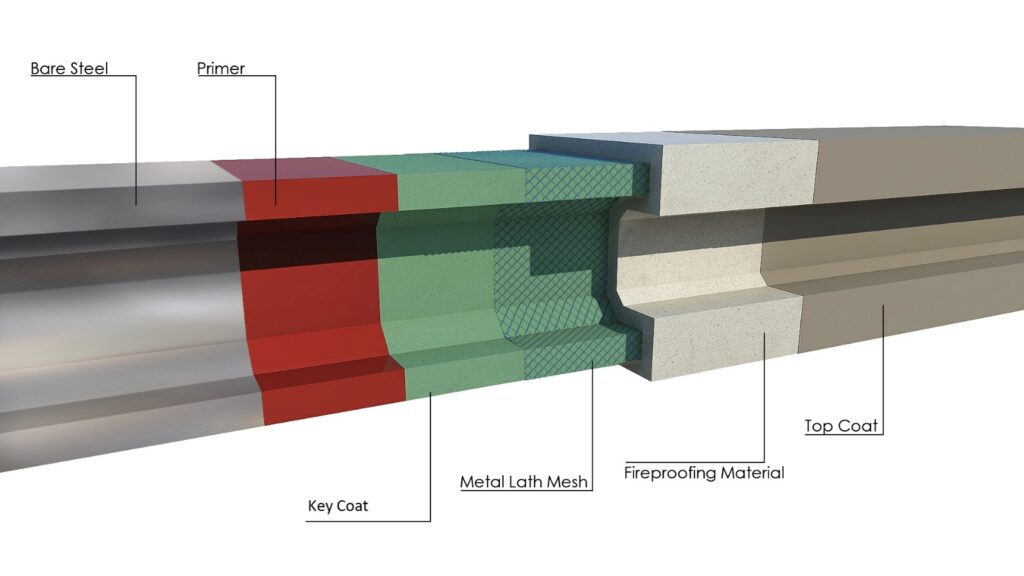

Structural Steel Fireproofing

When steel heats up during a fire, the structure gradually loses its load-bearing capacity at temperatures between 350 ºC to 750 ºC. Depending on the dead load on the structure, it would typically fail when the steel reaches temperatures between 500 to 600 ºC. Therefore, structural steel protection is required to preserve the stability of the building structure in the event of fire. The required thickness of each product depends on: The fire resistance requirement (typically 60, 90 or 120 minutes, sometimes even 180 or 240 minutes, in accordance with local legislation and mostly depending on the function and height and activities inside the building).

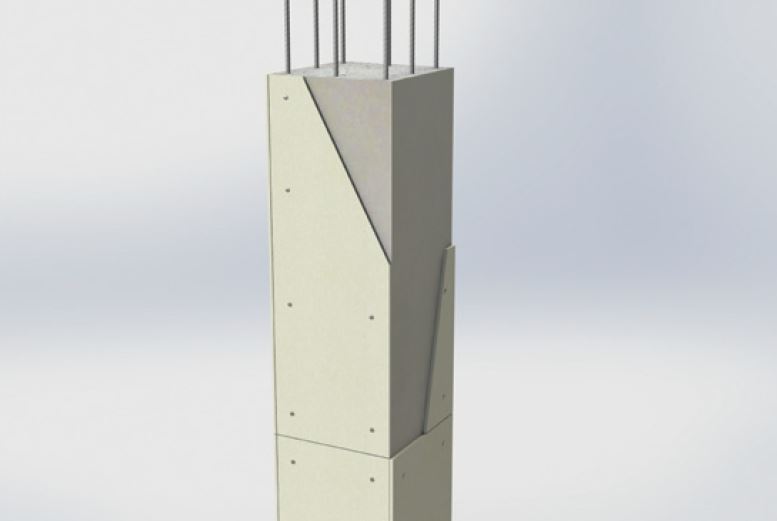

Structural Concrete protection

When concrete heats up during fire, at some point in time the steel reinforcement will heat up as well. The heating of the steel reinforcement is delayed by the concrete cover since the thermal transfer through the concrete is relatively slow. Moreover, at temperatures in a range of roughly 200-800 ºC the concrete itself loses its load-bearing capacity because of internal micro-cracking and chemical transformation (dehydration) of the cement phase. Typically, design standards simplify this gradual strength loss by assuming a limiting temperature of 500 ºC for concrete. Whenever the concrete cover thickness is insufficient to keep the steel reinforcement temperatures low enough to avoid collapse, or when spalling of concrete could occur or when the concrete itself is deteriorated, fire protection is needed.

Duct Fire Protection

The prevention of fire spread through ducted systems is of critical importance, fire is contained in a compartment as first and foremost in stopping the spread of fire in a building. In particular, passive fire protection is an effective measure to defense fire attack and uphold fire safety of the building.

Cable Tray Fire Protection

The prevention of fire spread through mechanical and electrical services is of critical importance, fire is contained in a compartment as first and foremost in stopping the spread of fire in a building. In particular, passive fire protection is an effective measure to defense fire attack and uphold fire safety of the building.

Fire Partition Wall

High performance lightweight Partition System

Efficient compartmentation is proven to be the best solution to contain fire and avoid it spreading throughout the building.

Hot & Cold Insulation

Hot insulation

Hot insulation on piping and Equipment’s for Oil Well Heads, Oil Field Platforms, cross country pipe, Marine Vessel Engine Rooms, Deck Head & Bulk Head, Chemical Plant Piping & Equipment’s, Boiler Accessories, Exhaust Ducting, Warehouses.

Cold Insulation

Cold Insulation for Centralized Cooling System Piping, Chillers, HVAC Ducting, Storage Plants, Chemical Plants etc.

Acoustic Insulation

Acoustic Insulation for various custom designed needs across Buildings, Malls, Marine Vessels etc.

Spray Applied Insulation - Thermoplaster

Innovative Spray applied insulation over most substrates with high thermal insulating & acoustic properties. The key Advantages are elimination of Thermal bridging, high Acoustic performance, can be applied on any architectural profiles including the difficult and complicated areas.

Thermal insulation: areas of application

- Refineries

- Chemical industry

- Food processing

- Wood and paper industries

- Heating, ventilation and air conditioning (HVAC)

- Natural gas storage tanks

- Biomass plants

- Buildings & Public facilities

Construction development nowadays is supported by the newest inventions in building materials. A more lightweight, sustainable and easier installation material are being considered. Especially for high rise apartments, Hotels or offices, the weight of the drywall and noise reduction becomes an important criterion that must be considered by the building owner and architects, in order to construct a more lightweight construction and quieter interior. Also due to recent innovations in manufacturing, the cost of Calcium silicate boards and Fiber Cement boards are widely considered in lieu of the traditional methods of construction.

Calcium Silicate Boards

Calcium silicate board is an asbestos-free thermal insulation product that can withstand continuous high operating temperatures. It is a light weight, low thermal conductive, high strength, easy to install, reliable and durable product. Industrial grade piping and equipment insulation is often fabricated from calcium silicate. It is a white free-flowing powder obtained by reacting calcium oxide and silica. It has a low bulk density and high physical water absorption.

Fibre Cement Boards

The characteristics of fibre cement make it ideally suited as exterior wall cladding material and as an interior building material as a tiling backer board or floor tiling base. As a building material, interior fibre cement tile backer board products are especially suited as a tiling base for tiling wet areas such as bathrooms, kitchens and showers areas as it is resistant to permanent water damage and does not need to be treated before tiling. Because it is water resistant, fibre cement tile backer board is used as an alternative to Plywood and Plasterboard tiling base. Installation of fibre cement backer board is easy and can be installed directly onto a stud wall or onto a wooden or timber floor.

Fibre cement as an exterior cladding material is used as an alternative to wood cladding or any traditional methods, since it is very durable and low maintenance, compared to other cladding materials. Fibre cement cladding is very durable because it is water resistant and does not rot, warp or crack. In addition, fibre cement cladding is a fire resistant building material and will not ignite when exposed to direct flame or extreme heat: it is a non-combustible material. Fibre cement cladding is easy to work with and to install.